The world of printing has grown immensely, now there are numerous ways and methods available to transfer designs and prints onto different objects. Each printing technique comes with its own set of benefits. In this article, we will be looking at different types of printing techniques on T-shirts in India. We at Bespoke Factory use these techniques to deliver custom-printed T-shirts. We consider your design requirements and material compatibility to make informed decisions, and provide high-quality printing services on T-shirts, mugs, totes and other items. Whether you need promotional items, personalised t-shirts, or customised products, the right printing method can help you achieve vibrant and durable end products.

Major Takeaways from this article-

- There are five major types of printing techniques on T-shirts commonly used: sublimation printing, screen printing, DTF (direct-to-film) printing, puff printing, and vinyl printing.

- Knowing which one of the types of printing techniques to use is important for ensuring that the printed designs on T-shirts will be of high quality, visually appealing, and long-lasting.

- Sublimation printing is ideal for polyester and polymer-coated surfaces, offering vibrant and long-lasting full-color prints.

- Screen printing is versatile and can be used on various materials, producing bold and opaque prints with high durability.

- DTF printing combines digital and screen printing, providing high-resolution prints with excellent detailing and color vibrancy.

- Puff printing adds texture and dimension to designs, creating a raised effect for visually striking prints.

- Vinyl printing offers versatility and durability, suitable for various surfaces and providing vibrant colors for advertising and signage purposes.

Let’s look at the five prominent types of printing techniques on T-shirts and other promotional products. We will also be discussing their benefits and drawbacks. By exploring the different types of printing on T-shirts and their specific applications, you can choose the most suitable technique to bring your designs to life.

1. Sublimation Printing

Sublimation printing technique is a common type of printing method on t-shirts transferring vivid and high-resolution graphics onto polyester and polymer-coated surfaces. This technology utilizes sublimation inks, which, when heated, transform into gas and enter the material, solidifying to produce a long-lasting, fade-resistant full-color print.

Understanding the workings of Sublimation Printing Technique

The process involves transferring dye from a solid to a gas state, allowing it to permeate the fibers of a substrate and become a permanent part of the material. The substrate is prepared and placed with the printed transfer paper in a heat press machine. Heat and pressure are applied, causing the ink to vaporize and penetrate the substrate’s fibers. As the temperature cools, the ink solidifies, bonding with the polyester fibers.

Application of Sublimation Printing Technique

The sublimation printing technique is widely utilized by us for the production of printed t-shirts, sportswear, promotional products, signs, and personalised gifts. We at Bespoke Factory aim to maximise customer satisfaction by delivering you quality apparel and accessories.

Pros of Sublimation Printing Technique:

- Vibrant and high-resolution prints: Sublimation printing as one of the most used types of printing techniques on T-shirts allows for the reproduction of intricate designs with rich and vivid colors, resulting in visually striking prints.

- Long-lasting and durable: The sublimation ink becomes a part of the material itself, ensuring that the print does not fade, crack, or peel off easily.

- Full-color printing: Sublimation printing technique enables the reproduction of full-color designs with gradients, shading, and complex patterns, without additional setup or color separation costs.

- Breathable and comfortable prints: The sublimation ink fuses with the fabric, allowing it to retain its breathability and softness, unlike some other printing methods.

Cons of Sublimation Printing Technique:

- Limited to polyester or polymer-coated surfaces: Sublimation printing is not suitable for natural fibers like cotton or non-coated materials, as the ink requires a polyester base to bond effectively.

- Higher cost for small orders: Sublimation printing is more cost-effective for larger production runs due to setup and equipment requirements. Smaller orders may have a higher per-unit cost.

- Requires specialized equipment: Sublimation printing requires a heat press machine and sublimation inks, which may involve a higher initial investment compared to other printing methods.

- Limited to light-colored backgrounds: Sublimation printing works best on lighter-colored materials, as the dye does not completely cover dark backgrounds, resulting in less vibrant prints. This is the biggest drawback of this type of printing method on T-shirts.

2. Screen Printing

Screen printing technique, often known as silkscreen printing is one of the types of printing techniques on t-shirts. It is a versatile technique that involves the process of depositing ink onto a substrate using a mesh screen. This method is well-known for producing colorful and opaque prints on a variety of surfaces, including cloth, paper, plastic, and metal.

Understanding the workings of Screen Printing Technique

The process of this popular method of printing on T-shirts starts with a fine mesh screen, usually made of polyester or nylon, stretched tightly over a frame. Areas of the screen that are not part of the design are blocked off using a stencil or emulsion. The design is then transferred onto the screen, creating open areas through which the ink can pass. The ink permeates the material, creating the desired design or image.

Application of Screen Printing Technique

Our Screen printing technique is ideal for large-scale manufacturing and designs with bright colours or fine details. It is often used to print clothing like personalised T-shirts, posters, labels, and packaging goods. As a commitment to excellence we at Bespoke Factory ensure high colour saturation and durability.

Pros of Screen Printing Technique

- Versatility: Screen printing can be used on a wide range of materials, including fabric, glass, metal, wood, and more.

- Long-lasting: The ink used in screen printing is typically highly durable, resulting in prints that can withstand repeated washing, exposure to sunlight, and general wear and tear.

- Vibrant and opaque prints: Screen printing allows for thick layers of ink to be applied, resulting in bold, opaque colors that stand out. This is one of the most popular types of printing techniques on T-shirts for this very reason.

- Cost-effective for large quantities: Screen printing becomes more cost-effective for larger production runs due to the setup time involved. Once the screen is prepared, reproducing the same design multiple times becomes more efficient.

Cons of Screen Printing Technique

- Limited detail: Fine details and intricate designs may be challenging to achieve in screen printing, especially when compared to digital printing methods.

- Setup time: Screen printing requires the creation of screens and stencils, which can be time-consuming and may not be practical for small quantities. This is one of the biggest disadvantages of this type of printing technique on T-shirts.

- Limited color blending: Screen printing is not as suitable for reproducing complex color gradients or photographic images, as it generally uses spot colors rather than full-color reproduction.

3. DTF (Direct-to-Film) Printing

DTF printing technique, also known as film transfer printing, is one of the relatively new types of printing techniques on T-shirts that combines the benefits of digital and screen printing. A specific film is utilized in the DTF printing technique to transfer the pattern to the substrate. Using this method we produce prints with excellent resolution and brilliant colors, allowing detailing and gradients.

Understanding the workings of DTF printing technique

DTF printing is a technique where a design is digitally printed onto a heat-transfer film using specialized inks, and the film is then laminated with an adhesive layer. The laminated film is placed on a prepared substrate, and heat and pressure are applied using a heat press machine, causing the adhesive to bond the film to the substrate while the ink sublimates and permeates the substrate’s fibers.

Application of DTF printing technique

DTF printing technique is one of the types of printing techniques on T-shirts that works with a variety of materials, including textiles, ceramics, glass, and wood. It is frequently used to create personalised printed t-shirts, garments, home decor, and promotional products.

Pros of DTF Printing Technique

- Versatility: DTF printing can be used on a wide range of substrates, including cotton, polyester, leather, and more. It offers the flexibility to print on various materials and surfaces.

- Vibrant and High-Resolution Prints: DTF printing allows for vibrant, high-resolution prints with rich colors and intricate details. It can reproduce complex designs accurately.

- Compatibility with Dark Substrates: Unlike some other printing methods, DTF printing can effectively transfer designs onto dark-colored substrates, providing versatility in design options.

- Soft and Flexible Prints: DTF prints result in soft and flexible finishes that maintain the natural texture of the substrate, making them comfortable to wear or use.

- Durability: When proper curing and post-processing techniques are applied DTF prints tend to be durable and long-lasting, with good resistance to fading and cracking over time.

Cons of DTF PrintingTechnique

- Initial Investment: DTF printing requires specialized equipment, including a DTF printer, heat press machine, and related accessories. The initial investment can be relatively higher compared to other printing methods.

- Post-Processing Requirements: DTF prints often require additional post-processing steps such as curing, washing, or applying a protective coating to enhance their durability and longevity. These additional steps can increase production time and costs.

- Environmental Impact: Some DTF inks may contain chemicals or additives that could have potential environmental impacts. Proper disposal or recycling practices should be followed to minimize environmental harm.

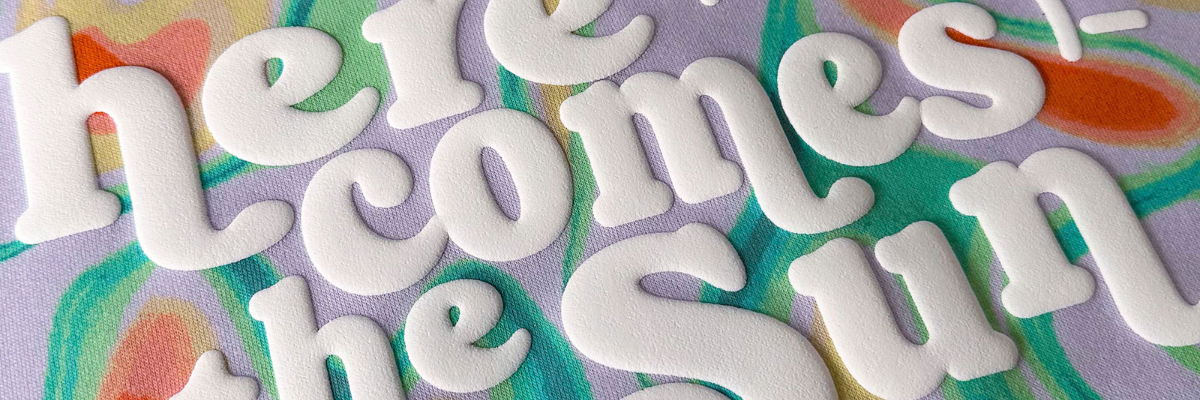

4. Puff Printing

Puff printing technique or embossed printing is one of the most unique and innovative types of printing techniques that adds texture and dimension to printed designs, bringing them to life in a whole new way. Whether used for custom t-shirts, promotional items, or artistic projects, puff printing offers a visually striking and tactile experience that sets it apart from traditional printing methods. This is one of the methods of printing on T-shirts that opens up endless possibilities for adding depth and interest to designs.

Understanding the workings of Puff Printing Technique

The process starts with the preparation of a design or artwork, considering the areas where the raised effect will be applied. Puff ink, a special type of ink that expands when exposed to heat, is then mixed and prepared. A screen is coated with a stencil or emulsion corresponding to the design, and ink is applied to the screen. Next, the ink is pushed through the stencil onto the substrate, such as fabric or paper. The printed substrate is then subjected to heat, causing the puff ink to expand and create the raised effect. Once cooled, the print retains its raised texture.

Application of Puff Printing Technique

This is one of the types of printing techniques on T-shirts that is excellent for adding texture and depth to designs, as well as giving them a raised aspect. Whether you want 3D graphics on your clothes, hats, purses, or eye-catching logos on accessories we at Bespoke Factory, cater to all your needs. We’re committed to providing you with high-quality prints and durable merchandise.

Pros of Puff Printing Technique:

- Textured and Raised Effect: Puff printing creates a three-dimensional, raised effect on the printed design, adding texture and depth to the print. It gives a unique and tactile quality to the finished product.

- Enhanced Design Impact: Puff printing technique can make designs stand out and grab attention. The raised texture adds visual interest and can make the design more appealing and impactful.

- Versatility: Puff printing can be applied to a variety of substrates, including fabrics, paper, and other materials. It offers versatility in creating textured prints on different surfaces.

Cons of Puff Printing Technique:

- Limited Detail and Precision: Puff printing may not be suitable for intricate or highly detailed designs. The raised texture can obscure fine details, making it challenging to achieve precision in the print.

- Limited Color Options: This is one of the types of printing on T-shirts that provides limited colour options. The raised effect is often achieved by adding a special puff ink, which may not be available in a wide range of colors.

- Restricted Application: Puff printing works best on flat or slightly curved surfaces. It may not be suitable for highly irregular or textured surfaces, as the puff effect may not adhere evenly or smoothly.

- Longer Production Time: Puff printing requires additional steps and curing time compared to regular printing methods. The added drying and curing process can increase production time and affect overall turnaround.

5. Vinyl Printing

Vinyl printing technique is one of the methods of printing on T-shirts that involves transferring a pattern from a carrier paper or film to a substrate using heat. The Plotter printing technique works well with a variety of materials, including textiles, ceramics, metal, and plastic. We at Bespoke Factory provide a wide range of design intricacy and color options.

Understanding the workings of Plotter Printing Technique

The process of Vinyl PrintingTechnique begins by creating a design digitally or using graphic design software. The design is then printed onto vinyl sheets or rolls using an inkjet printer or a solvent-based printer. The ink is formulated to adhere to the vinyl surface, creating vibrant and durable prints. After printing, the vinyl can be cut into desired shapes or sizes using a plotter cutter or a laser cutter. This is one of the types of printing techniques on T-shirts that provides high durability and versatility.

Application of Vinyl Printing Technique

The Plotter Printing Technique can be applied to various surfaces such as signs, banners, vehicles, walls, or windows, using adhesive backing or heat transfer methods. Vinyl printing is widely used in advertising, signage, vehicle graphics, and other applications due to its versatility, durability, and the ability to create vibrant and high-quality prints.

Pros of Vinyl Printing Technique

- Versatility: Vinyl printing method can be applied to various surfaces, such as signs, vehicles, walls, and windows, providing flexibility in usage.

- Vibrant Colors: Vinyl printing allows for vibrant and high-quality prints, making it suitable for advertising and signage purposes.

- Cost-Effective for small orders: Businesses looking for cost-effective ways for small orders should go for plotter printing techqiue.

Cons of Vinyl Printing Technique

- Limited Color Range: This is one of the types of printing on T-shirts that provides limited colour options. Traditional Plotter Printing Technique typically uses monochromatic pens or markers, limiting the color options for prints.

- Production Time: Vinyl printing can be time-consuming, especially for large quantities or complex designs, as each print is applied individually.

When it comes to types of printing techniques on T-shirts and other promotional products, understanding the different printing methods in India available is essential for achieving the desired results. Sublimation printing is excellent for vibrant, full-color designs on polyester-based materials, while screen printing offers versatility and durability. DTF technique the new face of printing technology, combines the benefits of digital printing and screen printing, providing high-resolution prints on various substrates. Puff printing adds texture and dimension to designs, creating a unique visual and tactile effect. Heat transfer printing is a versatile method suitable for different materials and design complexities. Using the appropriate printing techniques ensures quality products whether you require printing on T-shirts, custom-made hoodies, or other promotional items.

Each type of printing technique carries its own charm, but finding the most suitable one can make all the difference. Whether you’re a business placing bulk orders or an individual finding ways to upgrade their wardrobe being aware of the most suitable printing technique is a must. After all, these T-shirts will be more than mere garments; they will become a canvas for self-expression and cherished memories.

This article is all you need to determine the most suitable printing technique for your specific order. Whether you’re looking for high-quality results, cost-effectiveness, or versatility, this article has covered all the important factors to consider. If you have any questions or require further assistance, please don’t hesitate to leave a comment.